Design of a nozzle core with a thin wall enables batch application of coatings to cores.

Monolithic or one-piece core design produces a fluid conduit that offers very low resistance to fluid flow. Minimizing internal restriction enables coatings to flow freely during application and completely cover interior and exterior of core. Coatings fully encase the base metal, strengthening and enhancing surface finish of a nozzle wall on all sides. A nozzle wall around a core tip is converted from a hard angle to a radius at outside and inside diameter edges.

Hub material and coatings selected to provide an anti-stick surface are not good candidates for bonding with adhesive. Instead, coated cores are mechanically locked to hubs using external geometry to produce a two part assembly.

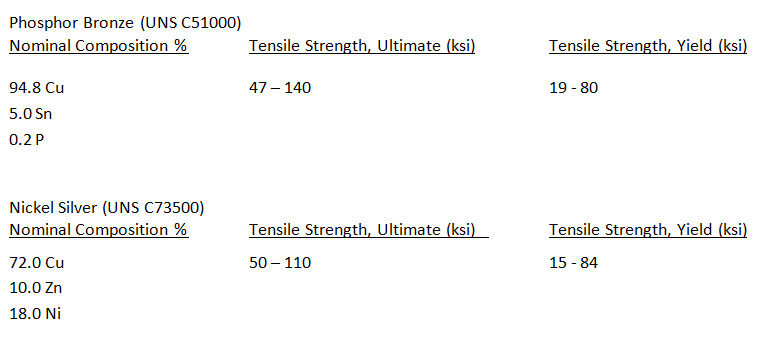

Nozzle cores are available in phosphor bronze UNS C51000 or nickel silver UNS C73500 base metals. They can be supplied uncoated or with a variety of different coatings applied to interior and exterior surfaces. Some mechanical properties of available base metals are listed in the Core Base Metal Property Table. Phosphor bronze has slightly higher mechanical properties and greater propensities to work harden. Bronze base metal is copper-colored. Nickel silver is a corrosion resistant brass with a silver appearance.

Core Base Metal Property Table

Coated surfaces enhance performance properties for some fluids compared to uncoated core surfaces.

-

- Smooths edges and covers asperities to provide more gradual transitions between sections.

- Promotes improved fluid transfer from a nozzle tip to a work-piece.

- Improves rigidity from increased wall thickness as a result of coating.

- Enhances resistance to reaction with chemically aggressive fluids.

- Increases resistance to wear from contact with abrasive fluids.

- Resists wicking and clinging of fluid to exterior tip surfaces.

Surfaces that are non-stick and do not wet to fluids they contact are appropriate to help reduce deposit variability by reducing affinity for fluid build-up and wicking, effectively promoting more consistent, less variable transfer of fluid to a work-piece. Repeatable transfer of a measured amount of fluid is important to ensure an automated application will be reliable. Coated surfaces maintain stability over time, ensuring effect of coating benefit is reproducible.

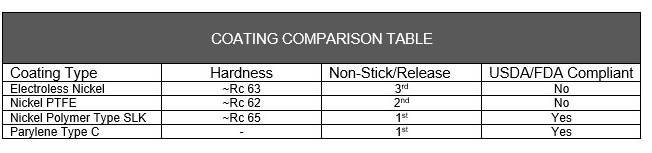

Selection is based on application requirements that dictate surface properties that are desirable to improve success of an application. A hard surface is advantageous when abrasive fluid is required for use in an application. Medical applications may require a USDA/FDA compliant coating.

A coating applied to a core increases thickness of a core wall by two times coating thickness. This reduces inside diameter of a core exit aperture by two times coating thickness and increases outside diameter by two times coating thickness. Core wall thickness varies from top to bottom. Nominal wall on a flange side of an uncoated core measures about 0.005 inch thick, exit aperture wall opposite a flange wall thins to less than 0.002 inch thick on small exit aperture cores. Nickel based coating applied to a core adds approximately 0.001 inch of thickness to a core wall overall, enhancing mechanical strength slightly by improving rigidity and surface hardness of a core. A 0.006 inch inside diameter core is reduced in size to around 0.005 inch inside diameter after coating.

Image of 23g phosphor bronze core with nickel PTFE tip (left side). Image of 0.006 inch ID nickel silver, nickel polymer tip (right side).

Coating thickness varies by coating type and method of application. Inside diameter of a core also has a limiting effect on thickness and type of coating that can be applied.

Coating Comparison Table

Coating comparison table lists nickel based coatings offered and some properties relative to one another. A hardness value for Parylene Type C is not entered since applied thickness is not generally adequate for applications where use of abrasive fluids could cause concern.

Sectioned Coated Nozzle Core

Image of a C-006-03-04-02 encased in acrylic and sectioned to show coating completely covers nozzle core interior wall. Although nozzles have been coated with an inside diameter as small as 0.002 inch, due to very limited demand, they have not been available as a standard product.